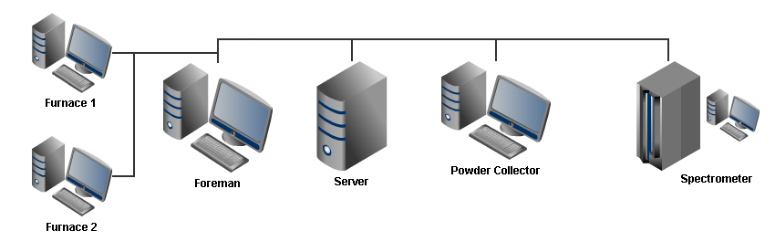

Example 1 AdjCalc

Process

Spectrometer with the integrated AdjCalc module. Analytical results are automatically transferred from the spectrometer software. The operator performs optimization and prints a weigh bill. All data is stored in the history log database, which is available for statistical analysis and reports.

Example 2 ProdCalc

- ProdCalc with the dependent AdjCalc module.

Process

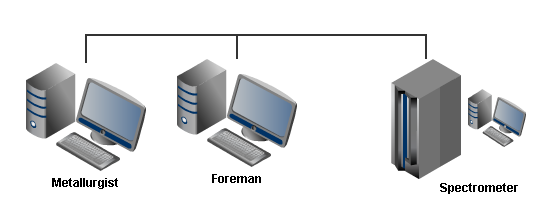

Spectrometer with Windows PC and ProdCalc and AdjCalc. Program Schedule is used for melt planning. Melt activity is documented with the modules Action and Charge. Analytical results are automatically transferred from the spectrometer software. The operator performs an optimization and prints a weigh bill. All data is stored in the history log database, which is available for statistical analysis and reports.

Example 3 ProdCalc

- AdjCalc and ProdCalc modules.

- Custom module for serial temperature input from a Digiterm temperature probe.

- Custom modules for monitoring furnace lining.

Process

Program Schedule is used for melt planning. Melt activity is documented with the modules Action and Charge. Temperature readings are automatically saved to the database. All data is stored in the history log database, which is available for statistical analysis and reports.

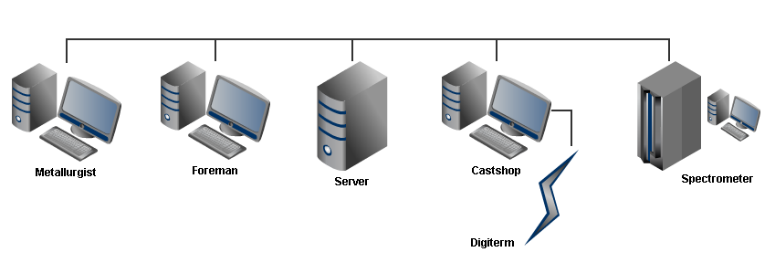

Example 4 AdjCalc Automation

- Adjustment module running in automatic mode.

- Custom module for reporting to production database as TCP/IP messages.

- Custom module for creating user messages based on calculation result and melt id.

- Custom module for displaying user messages at furnaces.

Process

The AdjCalc is integrated in a automated laboratory. The operator presents the sample to the robot and enters data using a barcode reader. Once the analysis is completed the results are automatically transmitted to the AdjCalc where the optimization is performed in automatic mode. The weigh bill is transferred to the current furnace station and presented on a monitor.

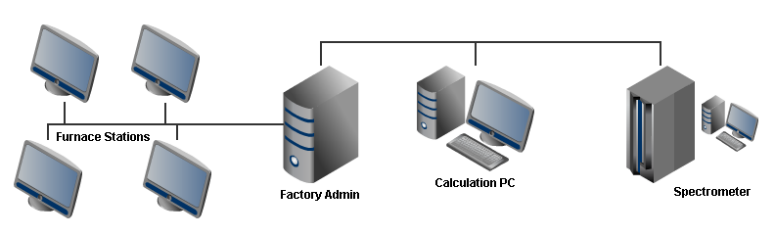

Example 5 ProdCalc Tube

- Adjustment and Designer modules.

- Customized Action module with production specific data input.

- Customized system and history log database.

- Custom module for melt counting after furnace relining.

- Custom module for powder receiving station.

- Custom module for displaying powder receiving station status at casting station.

- Microsoft Terminal Server and clients.

Process

Most programs are running in a Microsoft Terminal Server. The operators work with Terminal Server Clients. Program Schedule is used for melt planning and is operated by the foreman. Actions on melt are entered using the customized Action module and Charge. The laboratory is located away from production. Samples are transported by tube. The analysis result is transmitted back to the server. Adjustment calculation is performed at the furnace/casting station. When the powder collector enters the container ID into the system, a clear signal is displayed at the casting station. The history log database is used for transfer of production data to factory system.

Example 6 ProdCalc Movex

- Adjustment and Designer modules.

- Custom module for reading bar code labels produced by Movex resource planning system.

- Custom Active-X module as replacement for Action module.

Process

A new melt is defined in Movex. The foreman transfer melt info into the Charge Calculation system by scanning a bar code label, printed by Movex. The label contains charge number, quality name and amount.

The module Charge2Spectro is used for transferring charge info from the Charge Calculation database to the spectrometer. Adjustment calculation is made in the spectrometer computer.